The Ecological Challenge of Footwear

We wear shoes every day – they protect us, keep us comfortable, and express our personal style. But their production and disposal have a huge impact on the environment: in Germany alone, around 380 million pairs of shoes are thrown away each year – often because they are made of mixed materials that are nearly impossible to recycle. Clearly, we need more sustainable alternatives.

But what would a truly circular shoe look like?

This research explores whether it is possible to manufacture a shoe made entirely of wool that can be fully returned to natural cycles – without synthetic materials or chemical adhesives. Wool is a renewable raw material with impressive properties: it is biodegradable, dimensionally stable, water-repellent, elastic, and durable. However, its use as a shoe material also poses challenges - particularly in sole construction.

From Wool to Wearable Innovation

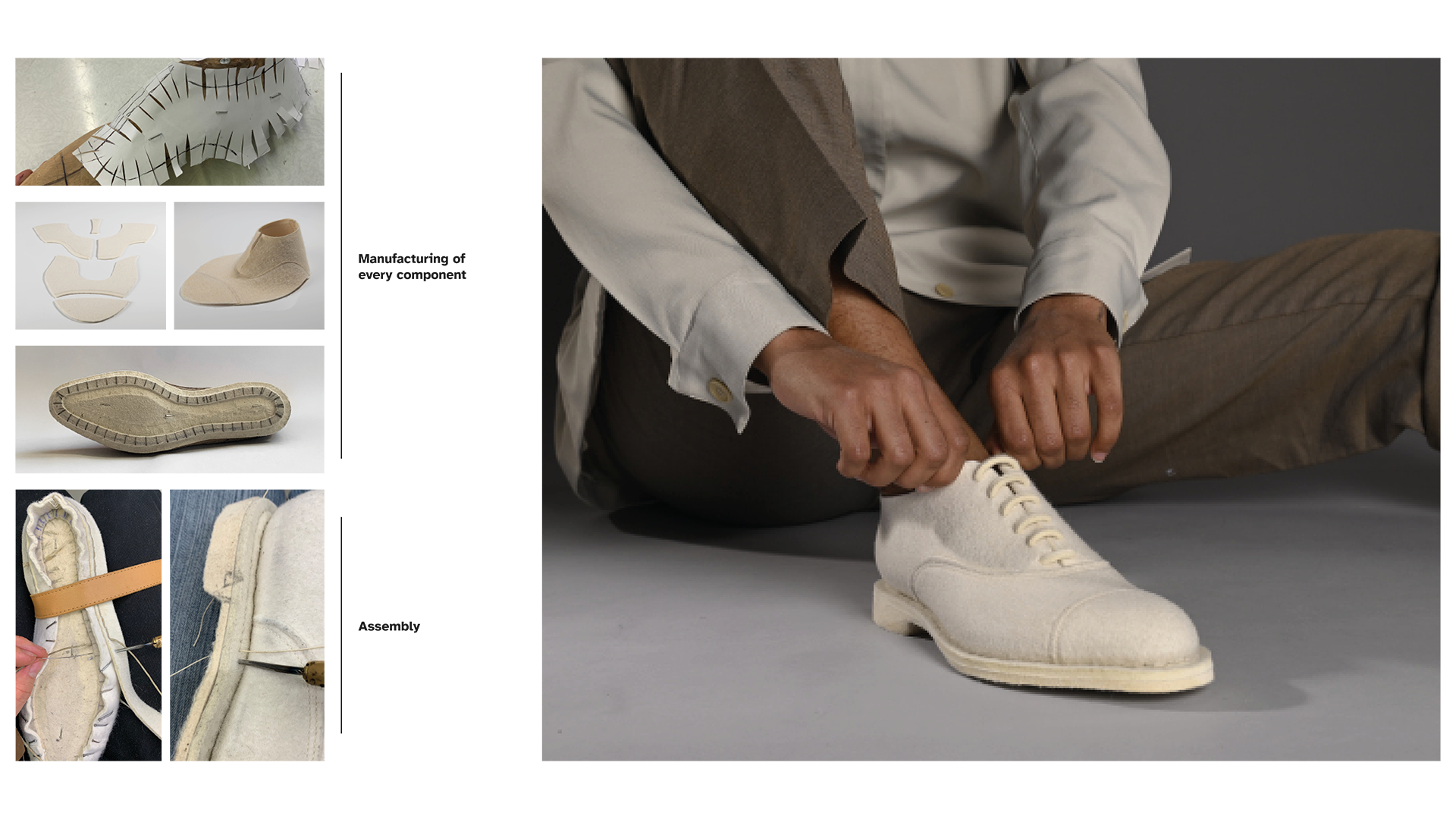

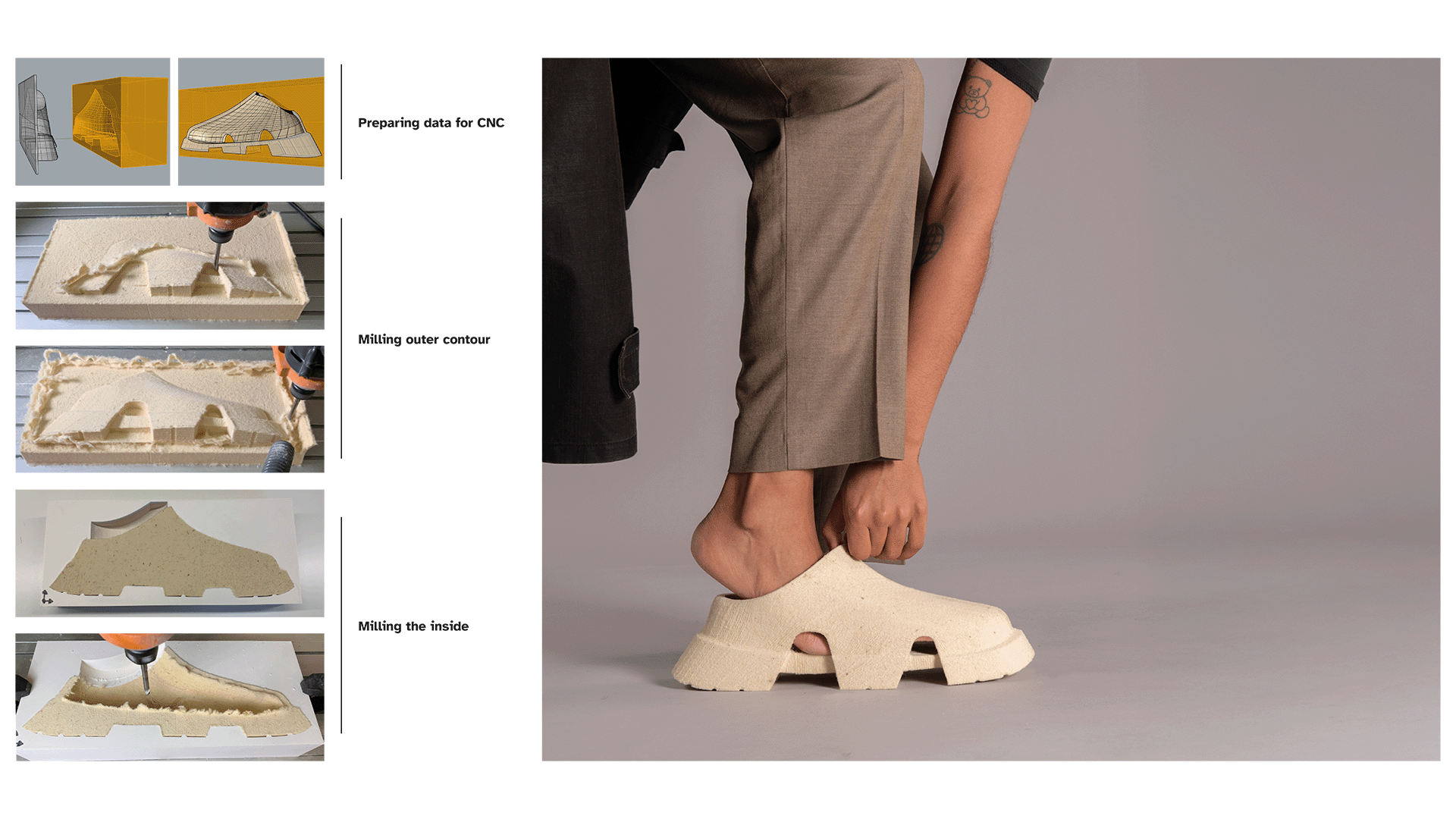

To test the suitability of wool for shoe production, extensive material experiments were carried out. The focus was on moldability, stability, repairability, and water resistance. Coatings such as lanolin or rubber, alternative joining techniques, and various shaping processes were tested.

During the research and the creation of numerous material samples, two contrasting prototypes emerged, differing significantly in both manufacturing methods and aesthetic approaches:

A Goodyear-welted brogue, which transfers traditional shoemaking methods and leatherworking techniques to the material wool.

A CNC-milled clog, which uses digital manufacturing processes to carve precise forms from a single block of felt.

Could Wool Transform the Future of Footwear?

The project highlights how circular design can reshape the future of the shoe industry. Beyond reducing waste and emissions, wool shoes might even be able to filter pollutants from the air through abrasion and return harmlessly to natural cycles at the end of their life. By revaluing wool, the project also supports regional sheep farming, strengthens biodiversity, and revives traditional handcrafts in combination with innovative technologies. Ultimately, it points toward a new, responsible model of production and consumption - where materials are used consciously, cycles are closed, and shoes become symbols of ecological transformation.

Dogs are allowed

Dogs are allowed

Free wifi available

Free wifi available

Toilets available

Toilets available

Partially wheelchair accessible

Partially wheelchair accessible

Wheelchair friendly toilet available

Wheelchair friendly toilet available